Hot Air Gun vs. Air Force Heater: Key Differences and Best Uses

Choosing between a hot air gun and an air heater can feel tricky, but it all comes down to what you need. A hot air gun is perfect for precision tasks like shrinking, welding, or stripping paint. On the other hand, air heaters are built for high-volume heating, making them ideal for larger-scale projects. Picking the right tool ensures you get the job done efficiently and effectively.

Key Takeaways

Hot air guns work well for detailed jobs like removing paint or melting ice in pipes. They give quick and focused heat, which is great for smaller projects.

Air heaters are better for big heating jobs. They are made for tasks like drying things or hardening glue, so they are good for factories or large spaces.

To pick one, think about your needs: use a hot air gun for easy control and moving around, and an air heater for steady heat in bigger areas.

What is a Hot Air Gun?

Definition and Functionality

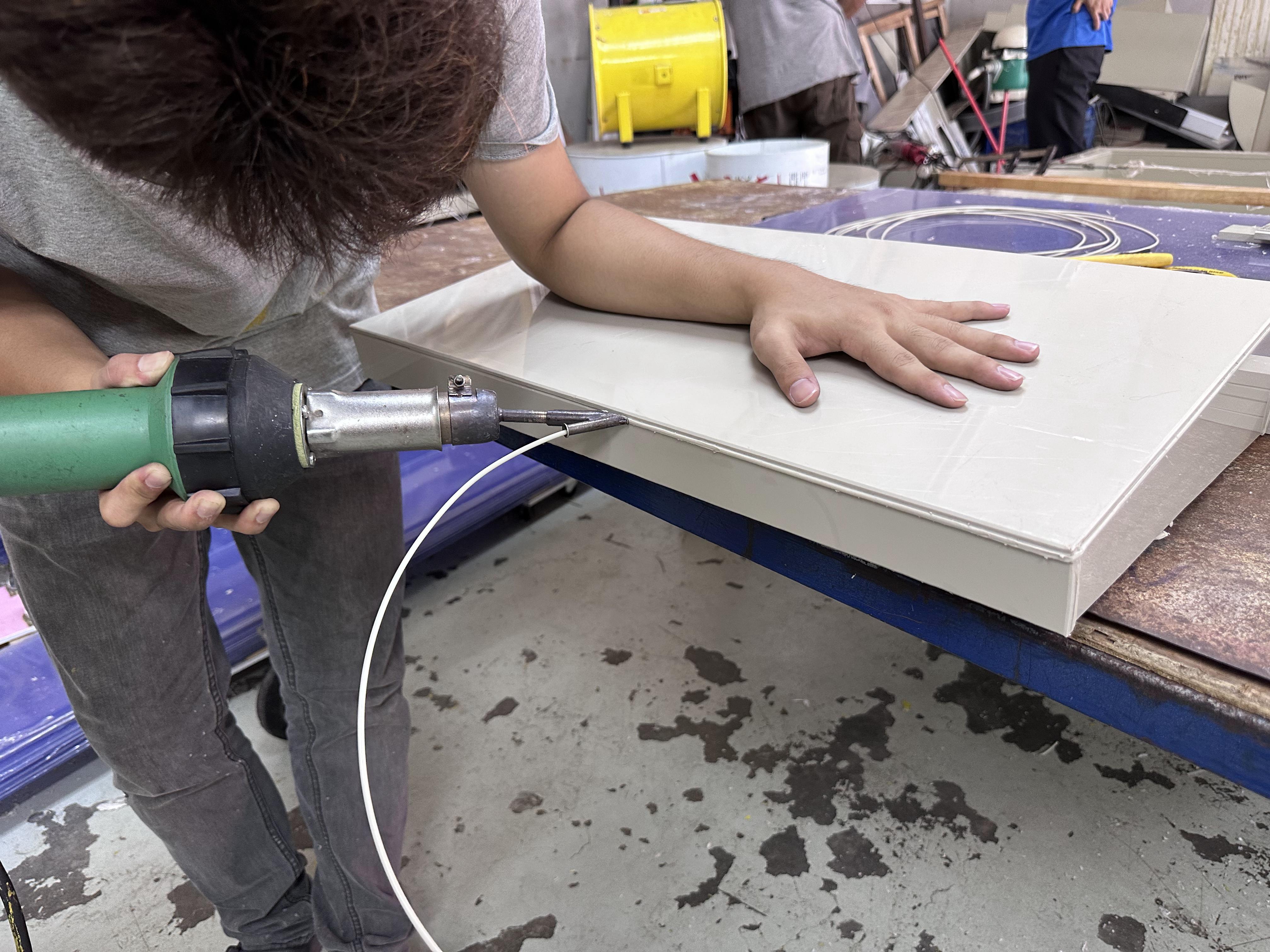

A hot air gun is a versatile handheld tool that produces a stream of heated air for various tasks. It operates using three key components: a heating element, a temperature control system, and an airflow control mechanism. The heating element, often made of high-resistance materials like nichrome wire, converts electrical energy into thermal energy. The temperature control system ensures the heat remains stable, while the airflow control adjusts the intensity and direction of the hot air. Together, these features make the hot air gun an efficient and reliable tool for precision work.

Common Applications

You’ll find hot air guns useful in a wide range of tasks. Here are some common applications:

Stripping paint or wallpaper.

Thawing frozen pipes.

Shaping or molding plastics.

Removing adhesives or flooring.

Upholstering or repairing furniture.

This tool is also popular in industrial settings for bending materials or applying heat shrink. Whether you’re a DIY enthusiast or a professional, a hot air gun can handle many tasks with ease.

Why Choose MM-Tech's Hot Air Gun?

MM-Tech’s hot air gun stands out for its reliability and efficiency. Designed with high-quality materials, it ensures consistent performance for all your heating needs. The ergonomic design makes it comfortable to use, even for extended periods. Plus, MM-Tech’s commitment to quality means you’re getting a tool that’s built to last. Whether you’re working on a small project or tackling a more demanding application, MM-Tech’s hot air gun delivers precision and control every time.

What are Air Heaters?

Definition and Functionality of Air Force Heaters

Air heaters are powerful devices designed to generate and distribute heat efficiently across larger spaces or for industrial processes. Unlike hot air guns, which focus on precision, air heaters rely on centrifugal force to move heated air through the environment. This makes them ideal for high-volume heating tasks. Air force heaters, a specific type of air heater, use advanced technology to ensure consistent air flow and temperature control. They’re built to handle demanding applications, providing reliable performance in both industrial and commercial settings.

Feature | Air Heaters | Hot Air Guns |

|---|---|---|

Primary Function | Generates heat to warm the environment | Blows heated air directly into the space |

Heat Distribution | Relies on centrifugal force for heat movement | Forces heated air out into the environment |

Speed of Heating | Generally slower in heating the space | Provides localized and immediate heat |

Suitability | More suitable for domestic settings | More effective in both commercial and domestic settings |

Common Applications of Hot Air Heaters

Hot air heaters are incredibly versatile and find use in various industries. You’ll often see them in:

Adhesive curing for cartons and tri-seals.

Heat shrinking for bulk packaging.

Drying processes.

Deflashing molded parts.

Staking, forming, and bending plastics.

These applications highlight their importance in industrial processes where precision and efficiency are key.

Key Features of Air Heaters

Air heaters come with several features that make them safe and efficient. Many models include a furnace pressure switch to monitor air pressure and ensure safe exhaust removal. A flame sensor shuts off the gas supply if no flame is detected, preventing dangerous gas build-up. Other safety features include:

Thermocouples to turn off the gas supply if the pilot light goes out.

Flame roll-out switches to stop flames from escaping the combustion chamber.

Plenum thermostat limit switches to prevent overheating by sensing air temperature.

These features ensure air heaters operate safely while delivering consistent performance. Whether you’re working in printing, textiles, or even the food and beverage industry, air heaters provide the reliability you need for large-scale heating tasks.

Key Differences Between Hot Air Guns and Air Heaters

Heat Generation and Output

When it comes to heat generation, hot air blowers and air heaters work differently. Hot air blowers produce heat by passing air through a heated element, which allows for immediate and targeted heating. This makes them perfect for tasks like stripping paint or working on a hot air rework station. On the other hand, air heaters don’t have an integrated air supply. They rely on external systems, which slows down heat distribution and results in longer warm-up times. If you need high heat output for industrial or domestic use, hot air blowers are the more versatile choice.

Air Supply and Volume

Hot air blowers combine the air source and heating element into one compact tool. This design ensures quick and efficient heat distribution. In contrast, air heaters require an external air supply, which complicates the system and slows down the process. For example, if you’re working on a project that demands immediate heat, like drying paint, a heat gun or hot air rework station will save you time and effort.

Portability and Size

Hot air guns are designed with portability in mind. They come in various sizes, from small handheld tools to larger industrial models, making them easy to carry and use. Unlike air heaters, which are bulkier and require external air supplies, hot air guns are more convenient for on-the-go tasks. Whether you’re repairing furniture or working in tight spaces, a heat gun offers the flexibility you need.

Precision and Control

If precision is your priority, hot air blowers are the way to go. They allow you to adjust settings like temperature and airflow, giving you full control over the heat application. This is especially useful for delicate tasks, such as shaping plastics or working on electronics with a hot air rework station. Air heaters, while powerful, lack the same level of control, making them better suited for broader heating applications.

Typical Use Cases

Hot air guns excel in tasks that require precision and portability. You can use them for stripping paint, thawing pipes, or even crafting projects. Air heaters, however, shine in industrial settings where high temperatures and large-scale heating are needed. For example, they’re ideal for adhesive curing or drying processes. Choosing the right tool depends on your specific needs and the scale of your project.

Best Uses for Each Tool

When to Use a Hot Air Gun

A heat gun is your go-to tool for precision tasks. It’s perfect when you need a targeted application of heat. For example, you can use it for stripping paint, softening adhesives, or even shrinking tubing. Its versatility makes it ideal for crafting projects like shaping plastics or creating custom wraps. If you’re working on small-scale tasks, such as thawing frozen pipes or repairing electronics, a heat gun offers the control you need.

You’ll also appreciate its portability. Whether you’re at home or on-site, this tool is easy to carry and operate. Plus, its temperature-controlled settings allow you to adjust the heat for delicate materials. If you’re looking for a reliable tool for quick and precise heating, a heat gun is the way to go.

When to Use Air Heaters

Air heaters shine in larger-scale or industrial applications. They’re built for high-volume heating, making them ideal for commercial settings or domestic settings that require consistent warmth. You can use them for drying processes, adhesive curing, or even deflashing molded parts. Their ability to handle large spaces and materials makes them a favorite in industries like packaging and textiles.

These heaters are also great for tasks that demand uniform heat distribution. For instance, if you’re working in a chamber or need to heat multiple objects simultaneously, air heaters deliver the power and efficiency you need. While they’re less portable than heat guns, their robust performance makes them indispensable for demanding jobs.

How to Decide Based on Your Needs

Choosing between a heat gun and an air heater depends on your specific requirements. Here are some tips to help you decide:

Temperature Control: If your task requires precise heat, go for a heat gun.

Air Flow Volume: For uniform heating over a large area, an air heater is better.

Environmental Conditions: Consider the size and material of your workspace.

Material Characteristics: Evaluate the shape and composition of what you’re heating.

Power Requirements: Ensure your tool matches the available voltage and amperage.

If you’re working on crafting or small repairs, a heat gun offers unmatched versatility. For industrial or large-scale tasks, air heaters provide the power you need. Think about your project’s scale and complexity, and you’ll make the right choice.

Choosing between a hot air gun and an air heater depends on your needs. Hot air guns excel in precision tasks, while air heaters handle large-scale heating. Always prioritize safety:

Keep flammable materials away.

Work in ventilated spaces.

Wear goggles and gloves.

For precision and reliability, MM-Tech’s hot air gun is your best choice!

FAQ

What safety precautions should you follow when using a hot air gun or air heater?

Always wear protective gear like gloves and goggles. Keep flammable materials away. Work in a well-ventilated area to avoid overheating or inhaling harmful fumes.

Can you use a hot air gun for industrial applications?

Yes, but only for small-scale tasks like heat shrinking or plastic welding. For larger industrial needs, air heaters are more efficient and powerful.

How do you maintain your hot air gun or air heater?

Clean the tool after every use.

Check for wear and tear regularly.

Store it in a dry, cool place to prevent damage.

See Also

Evaluating Top PPR Welding Machines Available in 2025

Your Ultimate Resource for Choosing PPR Welding Machines

Choosing the Right HDPE Sheet Welding Machine for 2025

CALL US DIRECTLY

NO.355, Youyi South Street, Qiaoxi District, Shijiazhuang, Hebei, China.

www.hdpeweldingmachine.com david@peweldingmachine.com