MM-Tech: A Decade of Excellence in Thermoplastic Welding Solutions

MM-Tech has established itself as a leader in thermoplastic welding solutions, showcasing a decade of excellence in innovation and quality. By developing advanced welding machines like CNC butt fusion and infrared butt fusion models, the company has consistently addressed the evolving needs of industries such as semiconductors and photovoltaics. Their commitment to adhering to rigorous DVS standards and collaborating with global partners highlights their dedication to delivering reliable and cutting-edge solutions. MM-Tech’s customer-focused approach and global impact have solidified its reputation as a trusted name in the industry.

Key Takeaways

MM-Tech has established itself as a leader in thermoplastic welding by developing advanced machines that meet the evolving needs of industries like semiconductors and photovoltaics.

The shift towards low-melt polyaryletherketone (LMPAEK)-based composites is revolutionizing the thermoplastic welding industry, offering enhanced performance and durability.

Automation and simulation technologies are key trends that improve precision and efficiency in welding processes, reducing costs and human error.

MM-Tech's commitment to rigorous DVS standards and global certifications ensures the quality and reliability of its welding solutions, building trust with customers.

Strategic collaborations with industry leaders and local suppliers have enabled MM-Tech to penetrate specialized markets and enhance its product offerings.

Sustainability is a core focus for MM-Tech, as the company develops energy-efficient machines and promotes environmentally conscious practices throughout its supply chain.

Looking ahead, MM-Tech plans to continue innovating and expanding its global presence, ensuring it meets the diverse needs of industries worldwide.

The Evolution of Thermoplastic Welding Solutions

Key Trends in the Industry

The thermoplastic welding industry has experienced significant advancements over the past decade, driven by technological innovation and evolving market demands. One of the most notable trends is the shift toward low-melt polyaryletherketone (LMPAEK)-based composites, which offer enhanced performance and durability. These materials have gained traction in industries requiring high-strength and lightweight solutions, such as aerospace and automotive manufacturing.

Automation has also emerged as a transformative force in thermoplastic welding. Advanced welding machines now incorporate automated systems that improve precision, reduce human error, and increase production efficiency. Simulation technologies have further enhanced this process by enabling manufacturers to test and optimize welding parameters before actual implementation. This trend has not only streamlined operations but also reduced costs for businesses.

The demand for lightweight materials in the automotive sector has fueled the growth of laser plastic welding. As automakers prioritize fuel efficiency and sustainability, high-performance plastic components have become essential. This shift has created opportunities for thermoplastic welding manufacturers to innovate and meet the industry's evolving needs.

"Thermoplastic composite structures have been certified and flying for decades," demonstrating the reliability and versatility of these materials in critical applications. Aircraft models like the Gulfstream G650 and Airbus A340 have successfully utilized thermoplastic welding, setting a benchmark for other industries.

Challenges and Opportunities in Thermoplastic Welding

Despite its advancements, the thermoplastic welding industry faces several challenges. The increasing size and complexity of welded structures require manufacturers to develop more sophisticated equipment and techniques. This demand has sparked debates on the certification of future welded structures, particularly in sectors like aerospace, where safety and reliability are paramount.

Global competition presents another challenge. European brands such as GF, ARGU, and SIMONA dominate certain markets, particularly in thermoplastic corrosion-resistant storage tanks and pipeline systems. However, companies like MM-Tech have seized this as an opportunity to innovate and carve out a niche. By developing advanced welding machines that adhere to rigorous standards, MM-Tech has positioned itself as a competitive player in the global market.

Collaboration with local suppliers and industry leaders has also opened new avenues for growth. For instance, MM-Tech's partnership with SIMONA sheets and pipes suppliers has enabled the company to penetrate specialized market segments effectively. These collaborations highlight the importance of building strong networks to overcome market challenges.

The future of thermoplastic welding holds immense potential. With continued innovation in materials, automation, and certification processes, the industry is poised to address its challenges while capitalizing on emerging opportunities.

MM-Tech’s Decade of Excellence in Innovation

Advanced Welding Machines

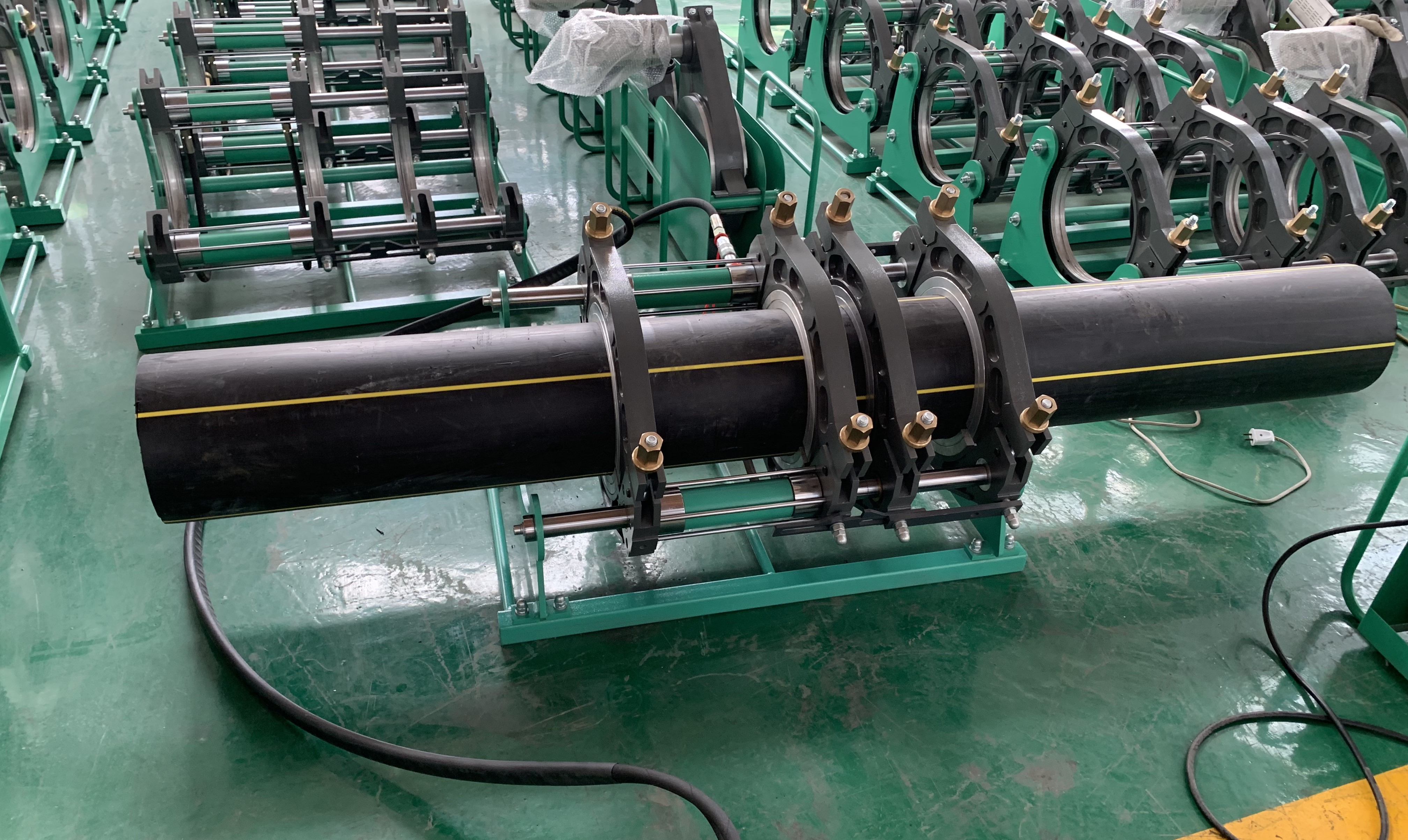

MM-Tech has demonstrated a decade of excellence by developing a diverse range of advanced thermoplastic pipe welding machines. These machines include CNC butt fusion welding machines, suspended butt fusion welding machines, infrared butt fusion welding machines, and sheet butt fusion welding machines. Each model is designed to meet the specific needs of industries such as semiconductors, photovoltaics, and surface treatment. By focusing on precision and efficiency, MM-Tech has ensured that its machines deliver consistent and reliable performance.

The CNC butt fusion welding machines stand out for their ability to automate complex welding processes. This automation reduces human error and enhances productivity, making them ideal for large-scale industrial applications. Suspended butt fusion welding machines, on the other hand, provide flexibility in handling challenging welding tasks, especially in confined spaces. Infrared butt fusion welding machines offer a contactless welding solution, ensuring clean and precise joints for thermoplastic pipes and fittings. Sheet butt fusion welding machines cater to specialized applications, enabling the seamless joining of thermoplastic sheets with high accuracy.

MM-Tech’s commitment to innovation has allowed it to address the evolving demands of the global market. By integrating advanced features and technologies, the company has positioned itself as a leader in producing high-quality thermofusion welding machines. This dedication to excellence has not only enhanced its product portfolio but also strengthened its reputation as a trusted provider of welding solutions.

Adherence to DVS Standards and Global Certifications

MM-Tech’s adherence to rigorous DVS standards and global certifications underscores its unwavering commitment to quality and reliability. These standards, established by the German Welding Society, set the benchmark for safety, performance, and durability in thermoplastic welding. By aligning its products with these stringent requirements, MM-Tech ensures that its advanced thermoplastic pipe welding machines meet the highest industry standards.

The company’s focus on compliance extends beyond DVS standards. MM-Tech actively pursues global certifications to validate the quality and performance of its products. This approach not only builds trust among customers but also facilitates market expansion. Industries that demand precision and reliability, such as aerospace and semiconductors, benefit from MM-Tech’s certified welding solutions.

By maintaining strict quality control measures and adhering to international standards, MM-Tech has carved out a niche in the competitive thermoplastic welding industry. Its dedication to excellence over the past decade has solidified its position as a global leader, enabling it to deliver innovative solutions that meet the diverse needs of its customers.

Strategic Market Penetration by MM-Tech

Expansion into Global Markets

MM-Tech has strategically expanded its presence across global markets, establishing itself as a trusted provider of thermoplastic welding solutions. Over the past decade, the company has leveraged its expertise to meet the growing demand for advanced welding machines in industries such as semiconductors, photovoltaics, and surface treatment. By focusing on innovation and quality, MM-Tech has successfully penetrated competitive markets traditionally dominated by European brands like GF, ARGU, and SIMONA.

The company’s ability to adapt its technology to meet regional needs has been a key driver of its global success. For instance, MM-Tech tailored its welding machines to address the specific requirements of the Malaysian semiconductor industry. This approach enabled the company to carve out a niche in a market heavily influenced by international players. MM-Tech’s commitment to understanding local market dynamics and delivering customized solutions has strengthened its foothold in diverse regions.

Participation in international trade shows and exhibitions has further amplified MM-Tech’s global reach. Events like Chinaplas 2025 provide a platform for the company to showcase its advanced equipment, including the SWT-PH and SWT-V series. These exhibitions not only highlight MM-Tech’s technological capabilities but also foster connections with potential clients and partners worldwide. By consistently demonstrating its expertise on a global stage, MM-Tech has reinforced its reputation as a leader in thermoplastic welding.

Collaborations with Industry Leaders

Collaborating with industry leaders has been central to MM-Tech’s market penetration strategy. The company has built strong partnerships with local suppliers and global manufacturers to enhance its product offerings and expand its market reach. For example, MM-Tech’s collaboration with SIMONA sheets and pipes suppliers has enabled it to deliver high-quality solutions tailored to the needs of specialized industries. These partnerships have also facilitated the seamless integration of MM-Tech’s welding machines into existing production systems.

MM-Tech actively engages with end-users to gather insights and refine its products. In 2024, Mr. David Xue, a key figure in the company, conducted an extensive business trip to Malaysia. During this visit, he met with clients to understand their challenges and gather feedback on MM-Tech’s solutions. This hands-on approach ensures that the company remains aligned with customer needs while fostering long-term relationships built on trust and reliability.

By collaborating with established players in the industry, MM-Tech has gained access to new technologies and market opportunities. These alliances have also strengthened the company’s ability to compete with European brands in high-demand sectors like thermoplastic corrosion-resistant storage tanks and pipeline systems. Through strategic partnerships, MM-Tech continues to drive innovation and deliver value to its customers.

Customer-Centric Approach: The MM-Tech Philosophy

Understanding and Addressing Customer Needs

MM-Tech places a strong emphasis on understanding the unique requirements of its customers. By engaging directly with clients, the company ensures that its solutions align with specific industry challenges. For instance, during a 2024 business trip to Malaysia, Mr. David Xue, a key figure at MM-Tech, met with end-users to gather insights and feedback. This proactive approach allowed the company to refine its offerings and address the evolving demands of the semiconductor industry.

The company’s dedication to customer satisfaction extends beyond product delivery. MM-Tech’s team of experts collaborates closely with clients to identify pain points and provide tailored solutions. A satisfied client once remarked, “Their strategic guidance and implementation of new technologies streamlined our operations and boosted our productivity.” Such testimonials highlight the company’s ability to not only meet but exceed customer expectations.

MM-Tech’s commitment to addressing customer needs has also led to the development of advanced welding machines that cater to diverse applications. By focusing on precision, efficiency, and reliability, the company has solidified its reputation as a trusted partner in thermoplastic welding solutions.

Building Long-Term Relationships Through Support and Training

MM-Tech believes that long-term relationships are built on trust, support, and continuous engagement. The company goes beyond selling products by offering comprehensive training programs tailored to the specific needs of its clients. A training recipient shared, “The personalized training was a game changer. MM-Tech took time to understand our specific needs and provided tailored training accordingly.” This hands-on approach ensures that customers can maximize the potential of MM-Tech’s welding machines.

Support does not end with training. MM-Tech provides ongoing assistance to its clients, ensuring seamless integration of its equipment into existing workflows. The company’s frontline sales team remains committed to delivering high-quality project solutions and addressing any challenges that arise. A project partner expressed their satisfaction, stating, “I am happy that together with MM-Tech we could deliver this project with high-quality standards.”

By fostering open communication and providing exceptional support, MM-Tech has cultivated lasting relationships with its clients. These partnerships have not only enhanced customer loyalty but also reinforced the company’s position as a leader in the thermoplastic welding industry.

Commitment to Quality and Sustainability

MM-Tech’s Mission and Vision for Excellence

MM-Tech has built its reputation on a foundation of quality and innovation. The company’s mission focuses on delivering advanced thermoplastic welding solutions that meet the highest industry standards. By prioritizing precision and reliability, MM-Tech ensures that its products consistently exceed customer expectations. This commitment has allowed the company to establish itself as a trusted provider in industries requiring robust solutions, such as semiconductors and photovoltaics.

The vision of MM-Tech extends beyond product excellence. The company aims to lead the thermoplastic welding industry by driving technological advancements and fostering sustainable practices. MM-Tech’s dedication to adhering to rigorous DVS standards reflects its pursuit of excellence. These standards ensure that every welding machine meets stringent safety and performance benchmarks, reinforcing the company’s position as a global leader.

MM-Tech’s focus on collaboration further strengthens its mission. By working closely with local suppliers and industry leaders, the company has developed innovative solutions tailored to specific market needs. For example, its partnerships in the Malaysian market have enabled MM-Tech to address the demand for thermoplastic corrosion-resistant storage tanks and pipeline systems. This strategic approach highlights the company’s ability to adapt and thrive in competitive environments.

“Quality is never an accident; it is always the result of intelligent effort.” MM-Tech embodies this philosophy by continuously refining its processes and products to deliver unmatched value to its customers.

Driving Sustainability in Thermoplastic Welding

Sustainability lies at the core of MM-Tech’s operations. The company recognizes the environmental impact of industrial processes and actively seeks to minimize its footprint. By developing energy-efficient welding machines, MM-Tech contributes to reducing resource consumption and waste in manufacturing. These innovations align with global efforts to promote sustainable practices across industries.

The adoption of advanced materials and techniques further underscores MM-Tech’s commitment to sustainability. For instance, thermoplastic composites welding has emerged as a game-changer in reducing manufacturing cycle times and material weight. According to CompositesWorld, automated out-of-autoclave (OOA) thermoplastic structures can cut production time by up to 80% and weight by up to 50% compared to traditional methods. MM-Tech integrates such advancements into its solutions, enabling customers to achieve both efficiency and environmental goals.

Laser plastic welding also plays a pivotal role in MM-Tech’s sustainability initiatives. This high-precision technique produces strong, clean welds with minimal thermal impact, making it ideal for applications requiring accuracy and minimal deformation. By incorporating this technology, MM-Tech ensures that its products meet the demands of modern industries while supporting sustainable development.

MM-Tech’s efforts extend beyond product innovation. The company actively engages with stakeholders to promote sustainable practices throughout the supply chain. By fostering partnerships with environmentally conscious suppliers, MM-Tech ensures that its operations align with global sustainability standards. This holistic approach reinforces the company’s commitment to creating a greener future for the thermoplastic welding industry.

Future Outlook: The Next Decade for MM-Tech

Plans for Continued Innovation

MM-Tech envisions a future driven by relentless innovation in thermoplastic welding technology. The company plans to expand its research and development efforts, focusing on creating advanced welding machines that cater to emerging industrial needs. By integrating cutting-edge technologies such as artificial intelligence and machine learning, MM-Tech aims to enhance the precision and efficiency of its products. These advancements will enable industries to achieve higher productivity while maintaining stringent quality standards.

The company also intends to explore new materials and welding techniques to address the evolving demands of sectors like aerospace, automotive, and semiconductors. For instance, lightweight thermoplastic composites are gaining prominence due to their strength and durability. MM-Tech seeks to develop specialized welding solutions that optimize the use of these materials, ensuring seamless integration into modern manufacturing processes.

"Innovation distinguishes between a leader and a follower." MM-Tech embodies this principle by continuously pushing the boundaries of what is possible in thermoplastic welding. The company’s commitment to innovation ensures that it remains at the forefront of the industry, delivering solutions that exceed customer expectations.

Expanding Global Impact and Market Reach

MM-Tech aims to strengthen its global presence by entering new markets and deepening its footprint in existing ones. The company plans to leverage its expertise to address the unique challenges of diverse industries worldwide. By tailoring its products to meet regional requirements, MM-Tech seeks to provide solutions that resonate with local customers.

Participation in international trade shows and exhibitions will play a pivotal role in this expansion strategy. These events offer a platform for MM-Tech to showcase its advanced welding machines and connect with potential clients and partners. The company’s presence at such events reinforces its reputation as a global leader in thermoplastic welding solutions.

Collaborations with industry leaders and local suppliers will further enhance MM-Tech’s market reach. By fostering strategic partnerships, the company can access new technologies and opportunities, ensuring its products remain competitive on a global scale. MM-Tech’s dedication to understanding customer needs and delivering tailored solutions will continue to drive its success in international markets.

The next decade holds immense potential for MM-Tech. Through continued innovation and strategic market expansion, the company is poised to solidify its position as a global leader in thermoplastic welding solutions.

MM-Tech has demonstrated unparalleled leadership in thermoplastic welding solutions over the past decade. By delivering advanced technologies like CNC butt fusion welding machines and adhering to rigorous DVS standards, the company has set benchmarks for quality and innovation. Its customer-centric philosophy and strategic collaborations have strengthened its global presence, making it a trusted partner for industries worldwide.

"Innovation distinguishes between a leader and a follower." MM-Tech embodies this principle, driving progress with cutting-edge solutions. With a clear vision for the future, MM-Tech remains committed to excellence, sustainability, and empowering businesses to achieve their goals.

FAQ

What industries benefit from MM-Tech’s thermoplastic welding solutions?

MM-Tech’s thermoplastic welding machines serve a wide range of industries, including semiconductors, photovoltaics, electroplating, and surface treatment. These industries rely on high-quality welding solutions for applications such as thermoplastic pipes, fittings, and corrosion-resistant storage tanks.

How does MM-Tech ensure the quality of its welding machines?

MM-Tech adheres to rigorous DVS standards established by the German Welding Society. These standards guarantee the safety, performance, and durability of its welding machines. Additionally, MM-Tech pursues global certifications to validate the reliability of its products.

What types of welding machines does MM-Tech offer?

MM-Tech provides a diverse range of advanced welding machines, including CNC butt fusion welding machines, suspended butt fusion welding machines, infrared butt fusion welding machines, and sheet butt fusion welding machines. Each machine is designed to meet specific industrial requirements.

How does MM-Tech address the needs of the semiconductor industry?

MM-Tech collaborates closely with local suppliers and industry leaders to develop tailored solutions for the semiconductor industry. The company’s welding machines meet the unique demands of this sector, ensuring precision and reliability in thermoplastic pipe and fitting applications.

What makes MM-Tech’s welding machines stand out from competitors?

MM-Tech integrates advanced technologies into its welding machines, such as automation and contactless infrared welding. These features enhance precision, reduce human error, and improve efficiency. The company’s commitment to innovation and adherence to international standards set it apart from competitors.

How does MM-Tech support its customers after purchase?

MM-Tech offers comprehensive training programs to help customers maximize the potential of their welding machines. The company also provides ongoing technical support and assistance, ensuring seamless integration into existing workflows and addressing any challenges that arise.

What role does sustainability play in MM-Tech’s operations?

Sustainability is a core focus for MM-Tech. The company develops energy-efficient welding machines and incorporates advanced materials to reduce resource consumption and waste. MM-Tech also collaborates with environmentally conscious suppliers to promote sustainable practices throughout its supply chain.

How has MM-Tech expanded its global presence?

MM-Tech has strategically entered global markets by tailoring its products to meet regional needs. Participation in international trade shows and collaborations with local suppliers have strengthened its market reach. The company’s ability to adapt and innovate has enabled it to compete with established European brands.

What steps does MM-Tech take to innovate its products?

MM-Tech invests heavily in research and development to create advanced welding machines. The company explores new materials, techniques, and technologies, such as artificial intelligence and machine learning, to enhance the precision and efficiency of its products.

What is MM-Tech’s vision for the future?

MM-Tech envisions a future driven by innovation and sustainability. The company aims to expand its global impact, develop cutting-edge welding solutions, and continue addressing the evolving needs of industries worldwide. MM-Tech remains committed to excellence and customer satisfaction.

See Also

CALL US DIRECTLY

NO.355, Youyi South Street, Qiaoxi District, Shijiazhuang, Hebei, China.

www.hdpeweldingmachine.com david@peweldingmachine.com